Ours is an eminent firm, engaged in manufacturing, supplying and exporting a comprehensive range of Pulp & Paper Mill Knives. These knives are designed using premium grade raw material, sourced from reliable vendors of market while keeping in mind the details specified by our patrons. Along with this, these knives are appreciated among the clients for their perfect grip, sharp edges, resistance against corrosion, light weight and durability. Under the offered array, we offer Paper Cutting Knife, Paper Trimming Knife, Paper Slitting Knife and Trimmer Knife.

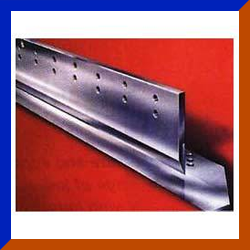

Our ranges Wood Chipper Knife are well known for quality, durability and reliability, as these are made by using advanced technology methods. These Wood Chipper Knife are used in various industrial applications. Our Wood Chipper Knife can be availed at industrial leading price.

Our ranges Wood Chipper Knife are well known for quality, durability and reliability, as these are made by using advanced technology methods. These Wood Chipper Knife are used in various industrial applications. Our Wood Chipper Knife can be availed at industrial leading price.

We are engaged in providing superior quality Wear Plate. These Wear Plate are processed using quality material under proper supervision. These are available at market leading prices as per client specification.

We are engaged in providing superior quality Wear Plate. These Wear Plate are processed using quality material under proper supervision. These are available at market leading prices as per client specification.

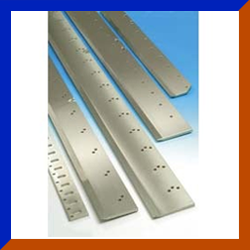

We are offering a superior quality range of Sheet Cutter Knife to our most valued clients. This range of Sheet Cutter Knife is made by using superior quality raw material. Our range of Sheet Cutter Knife is widely appreciated by our clients which are situated all round the nation and available at most competitive prices.

We are offering a superior quality range of Sheet Cutter Knife to our most valued clients. This range of Sheet Cutter Knife is made by using superior quality raw material. Our range of Sheet Cutter Knife is widely appreciated by our clients which are situated all round the nation and available at most competitive prices.

We are offering a wide range of Carbide Tipped Knife to our valuable customers. These Carbide Tipped Knife are provided by us at very reasonable price. These Carbide Tipped Knife are highly appreciated by our clients due to its durability.

We are offering a wide range of Carbide Tipped Knife to our valuable customers. These Carbide Tipped Knife are provided by us at very reasonable price. These Carbide Tipped Knife are highly appreciated by our clients due to its durability.

A side trimmer knife having a cylindrical body with a pair of exposed faces and a cutting edge at the periphery of at least one face, with the body being defined by a pair of juxtaposed cylindrical disks of hardened steel. The disks are held in rigidly aligned relation by a plurality of cap screws extended through aligned openings in each of the disks, with the openings tapering outwardly toward an exposed face of the knife body. The head and nut for each cap screw are also tapered to fit in the tapered openings to forcibly draw the disks toward each other and maintain their lock with the disks after repeated grinding of the faces of the body for the purpose of renewing the peripheral cutting edge

A side trimmer knife having a cylindrical body with a pair of exposed faces and a cutting edge at the periphery of at least one face, with the body being defined by a pair of juxtaposed cylindrical disks of hardened steel. The disks are held in rigidly aligned relation by a plurality of cap screws extended through aligned openings in each of the disks, with the openings tapering outwardly toward an exposed face of the knife body. The head and nut for each cap screw are also tapered to fit in the tapered openings to forcibly draw the disks toward each other and maintain their lock with the disks after repeated grinding of the faces of the body for the purpose of renewing the peripheral cutting edge